Debossing vs. Embossing: What’s the Difference and Which Should You Use?

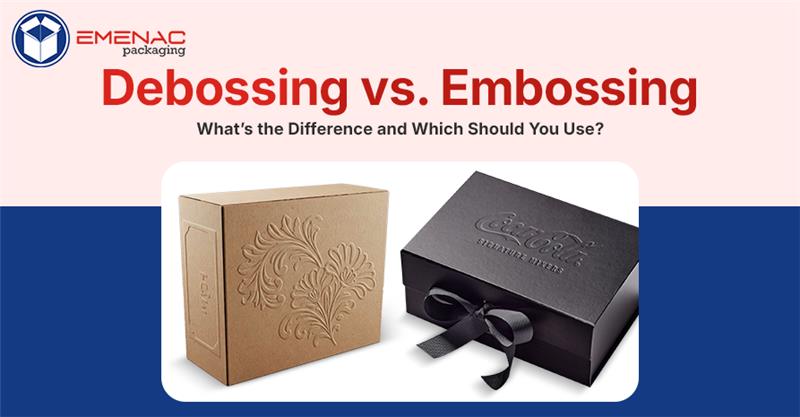

When you want to design your product packaging, you might have heard about debossing vs. embossing and wondered what the real difference is between the two.

Essentially, debossing sinks any part of the packaging you want to recess on the material surface, while embossing does the opposite, raises your artwork.

In the custom printed packaging process, the choice of choosing between the two depends on different things that we are going to discuss in this blog in detail. So, do not skip reading.

Debossing Vs. Embossing

Both deboss and emboss effects on packaging are highlighted; it all depends on you which finishing technique you want to use on your brand’s packaging. Let’s discuss how these processes work.

Debossing

Debossing creates a depressed effect on the surface of the packaging material, applied downward from the top. This recesses the logo into the packaging material. And debossing is less used compared to embossing because of its less striking appeal.

Embossing

Embossing is most commonly used to highlight brand logos. This process starts with a created die that makes the raised graphic on it that you want to highlight on your product, like a logo.

In this process, the plate is pressed into the product underneath, raising the specific part of the packaging design. This process is repeated multiple times because embossing dies are made from metal that is durable and can be used for both small & large-scale projects.

Major Differences that Set Them Apart

1. Cost-effectiveness

Debossing is more cost-effective as compared to embossing. You may be wondering why, as both processes are the same in nature, there is a little difference.

The embossing process is performed with additional metal elements, which increase the setup cost.

Debossing is cost-effective only when you do it without other customisations, but if you include any customisation along with debossing, the setup cost may increase too.

2. Aesthetics

Both techniques differ in their visual impact. If we talk about embossing, it increases the surface of the material up to 1/16".

Debossing, in comparison, indents the material up to 1/8" or more from the above. These techniques change the material’s appeal and feel, helping brands choose the right technique for their brand.

3. Ink Difference

The raised effect of embossing comes with sufficient visibility and contrast; less ink is used for this purpose.

On the contrary, debossing mostly relies on ink to make the debossed part more visible, especially on darker materials where enhanced visibility is hard to maintain.

4. Durability

Debossed designs are generally durable as they have a longer lifespan. Embossed details can show wear and tear or flatten within months, which shows it’s less durable as compared to debossing.

Hence, debossed effects are best for packaging that requires a long-lasting design or packaging that can’t be sold quickly within a few days or months.

4. Materials

Embossing is most effective to use for softer materials like paper, leather, and vellum. Softer materials can be easily melded to create a raised design.

On the other hand, debossing is best used on hard materials, which can maintain the indented impressions effectively.

Debossing vs. Embossing: Which Should You Use?

When deciding between embossing vs. debossing, consider the unique characteristics and features of each technique based on your brand’s packaging needs.

Embossing is best suitable if you want to stand out among the competition with elegant and raised patterns.

In comparison to embossing, debossing is a preferable choice for harder materials where packaging is intended to be used after a long period of time. Additionally, it’s cost-effective, making it a perfect choice for small businesses.

Conclusion!

In a nutshell, embossing and debossing are not only techniques; they add depth or detail to your packaging boxes. We outlined key differences that set them apart and also help you select the right finishing technique that best works for your packaging needs.

Emenac Packaging New Zealand specialises in all types of custom-printed packaging solutions that combine functionality, elegance, and a luxury feel. Our commitment to quality enhances customer satisfaction and urges them to order again from us.

Share This What Makes Custom Packaging Boxes so Beneficial for your Product?

What Makes Custom Packaging Boxes so Beneficial for your Product?

How Window Soap Boxes are Valuable for Your Brand Success?

How Window Soap Boxes are Valuable for Your Brand Success?

Matt Vs Gloss Lamination: Which One Is Better For Packaging

Matt Vs Gloss Lamination: Which One Is Better For Packaging

Custom Kraft Packaging Boxes: An Ultimate Guide about Types, Design, and Printing

Custom Kraft Packaging Boxes: An Ultimate Guide about Types, Design, and Printing

Top 5 Reasons Why Small Businesses Use Custom Printed Gable Boxes

Top 5 Reasons Why Small Businesses Use Custom Printed Gable Boxes